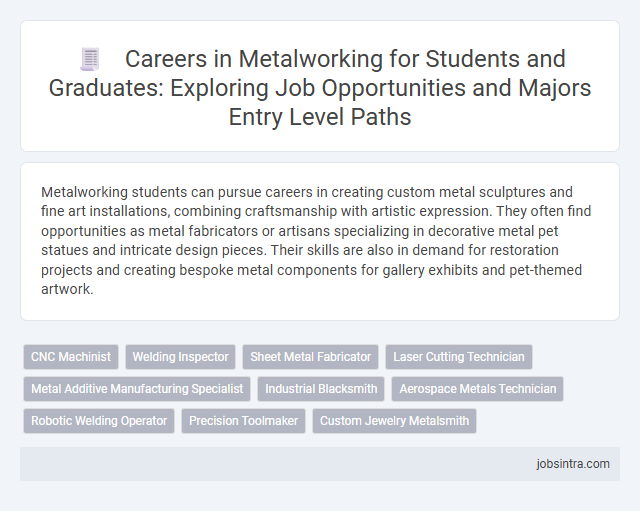

Metalworking students can pursue careers in creating custom metal sculptures and fine art installations, combining craftsmanship with artistic expression. They often find opportunities as metal fabricators or artisans specializing in decorative metal pet statues and intricate design pieces. Their skills are also in demand for restoration projects and creating bespoke metal components for gallery exhibits and pet-themed artwork.

CNC Machinist

CNC machinists operate computer-controlled machines to create precise metal parts used in manufacturing, automotive, and aerospace industries. They interpret technical blueprints, set up CNC machines, and monitor equipment to ensure accuracy and quality throughout the production process. Expertise in programming and machine maintenance allows CNC machinists to optimize workflow and produce high-quality components efficiently.

Welding Inspector

Welding inspectors play a critical role in ensuring the quality and safety of welded structures across industries such as construction, manufacturing, and shipbuilding. They examine welds for defects, verify compliance with industry standards, and use specialized equipment to perform non-destructive testing. Your expertise as a welding inspector helps prevent structural failures and guarantees the integrity of metalwork projects.

Sheet Metal Fabricator

Sheet metal fabricators shape, cut, and assemble metal sheets into components used in various industries, including construction, automotive, and aerospace. Your skills in reading blueprints, operating machinery, and welding are essential for producing high-quality metal products. This role offers hands-on experience and the opportunity to work with advanced fabrication technologies.

Laser Cutting Technician

Laser Cutting Technicians specialize in operating and maintaining laser cutting machines to precisely shape metal components according to design specifications. They analyze blueprints, adjust machine settings, and ensure high-quality cuts with minimal waste. Proficiency in CAD software and knowledge of metal properties enhance their efficiency and accuracy in manufacturing processes.

Metal Additive Manufacturing Specialist

Metalworking students can pursue a career as a Metal Additive Manufacturing Specialist, where they design, develop, and optimize 3D printing processes using metal powders and alloys. This role involves expertise in advanced manufacturing technologies, material science, and precision engineering to create complex metal parts for industries like aerospace, automotive, and medical devices. Your skills contribute to improving production efficiency and enabling innovative metal component fabrication with minimal waste.

Industrial Blacksmith

Industrial blacksmiths specialize in forging and shaping metal components used in manufacturing, construction, and machinery. They utilize traditional hammering techniques alongside modern machinery to create durable and precise metal parts. Career opportunities include working in automotive, aerospace, and heavy equipment industries, where metal fabrication skills are in high demand.

Aerospace Metals Technician

Aerospace Metals Technicians specialize in fabricating, inspecting, and repairing metal components used in aircraft and spacecraft, ensuring they meet rigorous safety and quality standards. Your skills in precision metalworking, knowledge of aerospace materials, and ability to operate advanced machinery make you essential in aerospace manufacturing and maintenance. Career opportunities include working for aerospace companies, defense contractors, and specialized repair facilities.

Robotic Welding Operator

Robotic Welding Operators play a crucial role in modern metalworking by programming and managing automated welding machines to ensure precision and efficiency. This job combines hands-on technical skills with knowledge of robotics and metallurgy, providing steady career growth opportunities in manufacturing sectors. You can expect to work closely with engineers and quality control teams to maintain high standards in production.

Precision Toolmaker

Precision toolmakers create and repair intricate tools, dies, and molds used in manufacturing, ensuring exact measurements and high-quality production. Your expertise in metallurgy, machining, and blueprint reading positions you to work in industries like automotive, aerospace, and electronics. Strong attention to detail and proficiency with CNC machines enable you to contribute to innovative product development and maintain production efficiency.

Good to know: jobs for Metalworking students

Introduction to Careers in Metalworking

Metalworking students have diverse career opportunities in the fine art industry. Your skills can lead to professions that combine craftsmanship and artistic expression.

- Artistic Metalworker - Create custom metal sculptures and decorative art pieces for galleries and private collections.

- Jewelry Designer - Design and fabricate unique metal jewelry using techniques like casting and engraving.

- Metalsmith for Restoration - Repair and restore historic metal artworks and artifacts with precision and care.

Importance of Metalworking in Fine Art

Metalworking students possess specialized skills valuable in various fine art careers, including sculpture, jewelry design, and restoration. Their expertise in shaping and manipulating metals allows for the creation of intricate and durable artworks.

The importance of metalworking in fine art lies in its ability to provide artists with diverse materials and techniques, enhancing creative expression. Metalworking contributes to the structural integrity and aesthetic appeal of fine art pieces, making it an essential discipline within the art world.

Relevant College Majors and Educational Pathways

Metalworking students interested in fine art can pursue careers such as sculptors, jewelry designers, and custom fabricators. Relevant college majors include Fine Arts with a focus on Metalwork, Industrial Design, and Metalsmithing. Your educational pathway typically involves earning a bachelor's degree in one of these areas, combined with hands-on experience in metalworking techniques.

Essential Skills and Competencies for Metalworking Careers

Metalworking students develop essential skills in precision, creativity, and problem-solving, which are crucial for careers in fine art metal sculpture, jewelry design, and custom fabrication. Mastery of techniques such as welding, casting, and metal finishing enhances craftsmanship and artistic expression, setting the foundation for professional success. Strong competencies in metalworking tools, material properties, and safety protocols ensure quality and innovation in artistic metal creations.

Entry-Level Job Opportunities for Students and Graduates

Metalworking students possess valuable skills in shaping and manipulating metals that open doors to various entry-level positions in the fine art industry. Opportunities include roles such as junior metal sculptor, metal fabricator, and art installation assistant.

Employers often seek candidates with hands-on experience in welding, soldering, and metal finishing techniques. Your expertise can lead to positions in galleries, art studios, and custom art fabrication companies.

Professional Growth and Specialization Areas

Metalworking students have diverse career opportunities in fine art, ranging from sculpture creation to restoration work. Professional growth often involves mastering advanced metal fabrication techniques and artistic design processes.

Specialization areas include custom jewelry design, architectural metal art, and large-scale metal sculptures. You can enhance your expertise by focusing on welding, casting, or metal finishing skills. Career advancement frequently depends on building a portfolio demonstrating creativity and technical precision.

Building a Successful Career in Fine Art Metalworking

| Job Opportunities for Metalworking Students in Fine Art |

|---|

| Metalworking students can pursue careers as sculptors, creating unique metal artworks for galleries and public installations. Skills in welding, forging, and fabrication are essential. Fine art foundry workers specialize in casting metal sculptures, contributing technical expertise in bronze, steel, or aluminum casting. Art fabricators assist artists by building complex metal structures, requiring precision and creativity. Restorers focus on conserving and repairing metal artwork, ensuring historical pieces maintain their integrity. Jewelry designers combine metalworking skills with artistic vision to produce custom, wearable art. Exhibition installers handle the safe transport and assembly of heavy metal art pieces in museums and galleries. |

| Building a Successful Career in Fine Art Metalworking |

| Developing mastery in metalworking techniques such as forging, stamping, and patination enhances your craftsmanship. Building a professional portfolio showcasing diverse metal artworks is crucial. Networking with artists, gallery owners, and curators opens career opportunities. Participating in art exhibitions and competitions raises visibility. Pursuing continuing education in contemporary metal art practices keeps skills relevant. Mastery of digital design software improves precision and innovation in creating metal art. Establishing a strong personal brand through social media and online galleries attracts clients and collaborators. Combining technical skill with creativity positions you as a sought-after metal artist in the fine art community. |

jobsintra.com

jobsintra.com