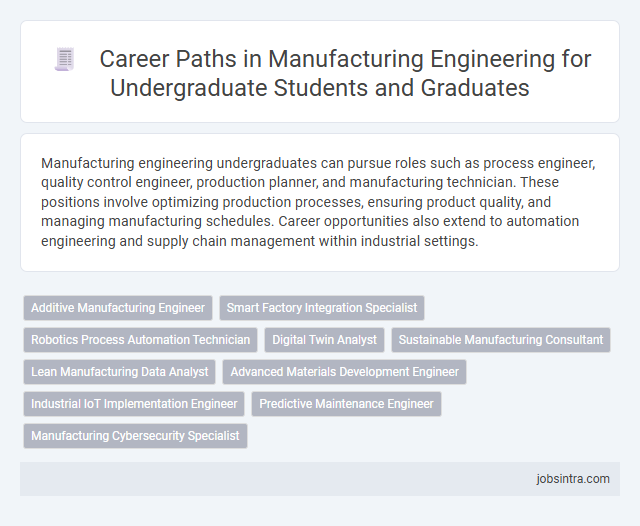

Manufacturing engineering undergraduates can pursue roles such as process engineer, quality control engineer, production planner, and manufacturing technician. These positions involve optimizing production processes, ensuring product quality, and managing manufacturing schedules. Career opportunities also extend to automation engineering and supply chain management within industrial settings.

Additive Manufacturing Engineer

Additive Manufacturing Engineers specialize in designing, developing, and optimizing 3D printing processes for producing complex components with enhanced precision and reduced waste. They collaborate with design and production teams to implement advanced materials and innovative manufacturing techniques, improving product performance and cost-efficiency. Expertise in CAD software, materials science, and process simulation is essential for success in this role.

Smart Factory Integration Specialist

Smart Factory Integration Specialists design and implement advanced automation systems to optimize manufacturing processes and increase production efficiency. Your role involves integrating IoT devices, robotics, and data analytics to create seamless, intelligent factory operations. Expertise in software platforms and industrial protocols enables effective communication between machines and systems for real-time decision-making.

Robotics Process Automation Technician

A Robotics Process Automation Technician specializes in designing, programming, and maintaining automated robotic systems to improve manufacturing efficiency and precision. Your skills in manufacturing engineering enable you to troubleshoot robotic equipment, optimize workflows, and implement innovative automation solutions. This role offers opportunities to work with advanced technologies that enhance production speed and quality control in industrial environments.

Digital Twin Analyst

A Digital Twin Analyst in manufacturing engineering leverages virtual models to simulate and optimize production processes, improving efficiency and reducing downtime. You analyze data from real-time operations to predict maintenance needs and enhance product quality. This role blends engineering expertise with advanced analytics, making it vital for smart factory initiatives and Industry 4.0 transformations.

Sustainable Manufacturing Consultant

Sustainable Manufacturing Consultants specialize in developing eco-friendly production processes that reduce waste and energy consumption while maintaining efficiency and quality. Your expertise in materials, process optimization, and environmental regulations helps companies implement green manufacturing practices that align with sustainability goals. This role combines engineering knowledge with environmental stewardship to drive innovation in sustainable industrial operations.

Lean Manufacturing Data Analyst

Lean Manufacturing Data Analysts specialize in optimizing production efficiency by analyzing data to identify waste and streamline processes within manufacturing settings. Your skills in data interpretation and process improvement contribute to cost reduction and enhanced product quality. This role bridges engineering principles with data-driven strategies to support continuous improvement initiatives in manufacturing operations.

Advanced Materials Development Engineer

Advanced Materials Development Engineers in manufacturing engineering focus on creating and testing innovative materials to enhance product performance and durability. They work closely with research and development teams to design materials that meet specific industrial requirements, utilizing knowledge of metallurgy, polymers, and composites. Proficiency in material characterization techniques and collaboration with production processes are key to optimizing manufacturing efficiency and product quality.

Industrial IoT Implementation Engineer

Industrial IoT Implementation Engineers specialize in integrating smart devices and sensors into manufacturing systems to enhance automation and data analytics. They design and deploy interconnected networks that optimize production processes, improve equipment efficiency, and enable predictive maintenance. Their expertise bridges manufacturing engineering principles with advanced digital technologies to drive Industry 4.0 transformations.

Predictive Maintenance Engineer

Predictive Maintenance Engineers analyze data from manufacturing equipment to forecast potential failures and schedule timely maintenance, minimizing downtime and reducing costs. They utilize advanced sensors, machine learning algorithms, and IoT technologies to monitor machine health in real-time. Their expertise ensures continuous production efficiency and extends the lifespan of critical machinery in manufacturing plants.

Good to know: jobs for manufacturing engineering undergraduate

Introduction to Manufacturing Engineering Careers

Manufacturing engineering offers diverse career paths that blend technical skills with innovative problem-solving. This field focuses on improving production processes to increase efficiency, quality, and sustainability.

- Process Engineer - Designs and optimizes manufacturing processes to enhance product quality and reduce costs.

- Quality Engineer - Ensures manufacturing standards are met by implementing testing and quality control systems.

- Production Planner - Coordinates production schedules to meet demand while minimizing waste and downtime.

Your background in manufacturing engineering prepares you to contribute to manufacturing excellence across various industries.

Key Roles and Job Opportunities in Manufacturing Engineering

Manufacturing engineering undergraduates have diverse career paths in industries focusing on production efficiency and technology integration. Job opportunities span various sectors emphasizing design, process improvement, and quality management.

- Process Engineer - Optimizes manufacturing processes to increase efficiency and reduce costs in production lines.

- Quality Control Engineer - Ensures products meet industry standards through rigorous testing and quality assurance protocols.

- Production Supervisor - Manages day-to-day manufacturing operations, coordinating teams and resources to meet production targets.

Essential Skills and Qualifications for Manufacturing Engineers

Manufacturing engineering undergraduates qualify for roles such as process engineer, quality engineer, and production supervisor. These positions require a strong understanding of manufacturing processes, materials science, and industrial systems.

Essential skills include proficiency in CAD software, knowledge of lean manufacturing principles, and expertise in quality control methodologies. A background in problem-solving, project management, and data analysis is crucial for success in manufacturing engineering careers.

Emerging Technologies and Trends in Manufacturing Engineering

Manufacturing engineering undergraduates have expanding career opportunities driven by emerging technologies such as additive manufacturing, robotics, and Industry 4.0. Expertise in digital twins, IoT integration, and smart factory automation enhances job prospects in advanced manufacturing sectors.

Roles include process engineer positions focused on optimizing automated production lines using AI and machine learning algorithms. Jobs in sustainability engineering involve developing eco-friendly manufacturing methods and materials recycling techniques. Careers in supply chain analytics leverage big data to improve efficiency and reduce costs in global manufacturing operations.

Internship and Work Experience Pathways for Students

| Job Role | Description | Internship Opportunities | Work Experience Pathways |

|---|---|---|---|

| Process Engineer Intern | Assist in optimizing manufacturing processes to improve efficiency and reduce waste. Learn to analyze production data and implement process improvements. | Internships at automotive, aerospace, and electronics manufacturers offer hands-on experience with process design and quality control. | Entry-level positions in process engineering allow gaining expertise in workflow analysis, lean manufacturing, and Six Sigma methodologies. |

| Quality Control Intern | Support the quality assurance team by performing inspections, ensuring product standards, and documenting compliance with industry regulations. | Internships in consumer goods and industrial product companies provide experience in quality control systems and testing procedures. | Roles in quality engineering help develop skills in statistical process control, root cause analysis, and corrective action implementations. |

| Manufacturing Engineer Intern | Engage with production teams to design, test, and improve manufacturing systems for higher productivity and lower costs. | Internships at large-scale manufacturing plants allow for exposure to CAD software, automation tools, and project management. | Work experience includes roles focusing on equipment maintenance, production scheduling, and continuous improvement projects. |

| Industrial Engineering Intern | Develop skills in optimizing human and material resources in manufacturing environments to maximize output and efficiency. | Internships often include work on time-motion studies, facility layout planning, and inventory control. | Career pathways involve positions in supply chain management, production planning, and operational efficiency analysis. |

| Research & Development Intern | Participate in product design and development processes, experimenting with materials and manufacturing techniques. | Internships in R&D departments of technology firms foster innovation skills and familiarity with prototyping equipment. | Experience gained includes product lifecycle management, testing protocols, and collaboration with cross-functional teams. |

| Maintenance Engineering Intern | Assist with the maintenance and troubleshooting of manufacturing equipment to minimize downtime and improve reliability. | Industrial plant internships provide exposure to predictive maintenance, calibration procedures, and safety protocols. | Work roles include preventive maintenance planning, equipment optimization, and root cause failure analysis. |

| Your Path to Success | Internships encourage real-world application of manufacturing engineering principles. Your active involvement in internships and work experiences strengthens technical proficiency, enhances problem-solving skills, and builds professional networks essential for career growth in manufacturing engineering. | ||

Professional Certifications and Further Education Options

Manufacturing engineering undergraduates have diverse job opportunities that often require professional certifications to advance. Pursuing further education enhances expertise and opens doors to specialized roles in the manufacturing sector.

- Certified Manufacturing Engineer (CMfgE) - This certification validates skills in production processes and quality control, increasing job prospects in manufacturing firms.

- Lean Six Sigma Certification - Focuses on process improvement and waste reduction, making candidates valuable for efficiency-driven manufacturing roles.

- Master's Degree in Manufacturing or Industrial Engineering - Provides advanced knowledge and research opportunities, enabling access to leadership or R&D positions.

Strategies for Career Advancement in Manufacturing Engineering

Manufacturing engineering undergraduates can pursue roles such as process engineer, quality control engineer, and production supervisor. Developing expertise in automation technologies and lean manufacturing principles enhances job performance and marketability. Networking with industry professionals and obtaining relevant certifications like Six Sigma contribute significantly to career advancement.

jobsintra.com

jobsintra.com