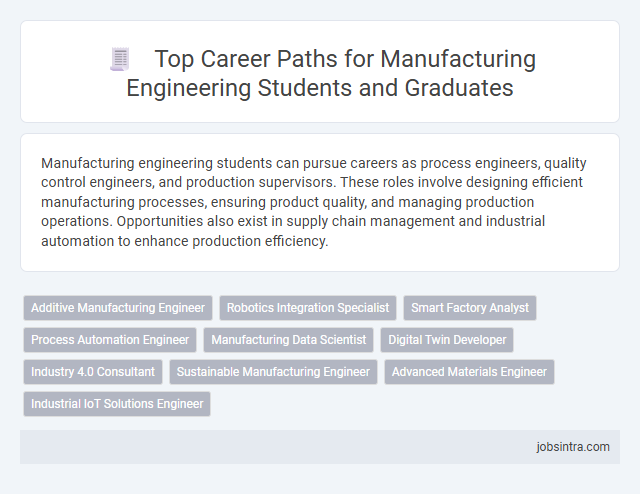

Manufacturing engineering students can pursue careers as process engineers, quality control engineers, and production supervisors. These roles involve designing efficient manufacturing processes, ensuring product quality, and managing production operations. Opportunities also exist in supply chain management and industrial automation to enhance production efficiency.

Additive Manufacturing Engineer

Additive Manufacturing Engineers specialize in designing and optimizing 3D printing processes for industrial applications. They develop innovative manufacturing solutions that reduce material waste and improve production efficiency. Your skills in CAD software and materials science are essential for creating precise prototypes and functional parts.

Robotics Integration Specialist

Robotics Integration Specialists focus on incorporating advanced robotic systems into manufacturing processes to improve efficiency and precision. You will analyze production workflows, design automation solutions, and oversee the installation and testing of robotic equipment to optimize manufacturing operations. This role bridges engineering expertise with hands-on technical skills to drive innovation in automated manufacturing environments.

Smart Factory Analyst

Smart Factory Analysts play a crucial role in transforming traditional manufacturing processes through the integration of advanced technologies like IoT, AI, and data analytics. You will analyze production data to optimize efficiency, reduce downtime, and improve overall operational performance in smart factories. This role offers manufacturing engineering students a future-focused career path that combines technical knowledge with innovative problem-solving skills.

Process Automation Engineer

Process Automation Engineers design and implement automated systems to optimize manufacturing processes, enhancing efficiency and reducing costs. They utilize skills in robotics, control systems, and software programming to streamline production workflows. These engineers play a crucial role in integrating advanced technologies such as IoT and AI to improve operational accuracy and productivity.

Manufacturing Data Scientist

Manufacturing Data Scientists analyze complex data to optimize production processes, improve quality control, and reduce operational costs. Your expertise in both engineering principles and data analytics enables you to develop predictive models and automate decision-making in manufacturing environments. This role offers a dynamic career path where technology and engineering intersect to drive innovation on the factory floor.

Digital Twin Developer

Manufacturing engineering students can pursue a career as Digital Twin Developers, where they create virtual replicas of physical systems to optimize production processes and predict maintenance needs. This role involves using advanced simulation software, data analytics, and IoT technologies to enhance operational efficiency and reduce downtime. Your expertise in both manufacturing processes and digital tools makes you a valuable asset in driving innovation through accurate digital modeling.

Industry 4.0 Consultant

Industry 4.0 consultants specialize in integrating advanced digital technologies such as IoT, AI, and automation into manufacturing processes to enhance efficiency and productivity. They analyze existing production systems, recommend smart factory solutions, and oversee the implementation of cutting-edge Industry 4.0 strategies. Manufacturing engineering students equipped with knowledge in data analytics, cyber-physical systems, and process optimization are well-suited for this in-demand role.

Sustainable Manufacturing Engineer

Sustainable Manufacturing Engineers play a crucial role in designing eco-friendly production processes that minimize waste and reduce energy consumption. They develop innovative solutions to improve resource efficiency while ensuring product quality and compliance with environmental regulations. Your expertise in sustainable practices can drive greener manufacturing systems that benefit both the company and the planet.

Advanced Materials Engineer

Advanced Materials Engineers develop and test new materials to enhance product performance and durability in manufacturing processes. Your expertise in materials science and engineering principles enables you to innovate within industries such as aerospace, automotive, and electronics. This role demands strong problem-solving skills and knowledge of material properties to optimize manufacturing efficiency and quality.

Good to know: jobs for manufacturing engineering students

Overview of Manufacturing Engineering Careers

Manufacturing engineering offers diverse career paths in industries such as automotive, aerospace, electronics, and consumer goods. Graduates focus on improving production processes, quality control, and product design to drive efficiency and innovation.

- Process Engineer - Designs and optimizes manufacturing workflows to enhance production efficiency and reduce costs.

- Quality Assurance Specialist - Monitors product standards and implements quality control systems to ensure reliable output.

- Manufacturing Engineer - Develops and integrates new technologies and equipment for advanced manufacturing solutions.

In-Demand Job Roles for Manufacturing Engineers

Manufacturing engineering students have a wide array of career opportunities that focus on improving production processes and optimizing operational efficiency. These roles are crucial in advancing technology and maintaining competitive manufacturing industries.

- Process Engineer - Designs and implements manufacturing processes to enhance productivity and reduce waste.

- Quality Engineer - Ensures that products meet industry standards and customer expectations through rigorous testing and inspection.

- Automation Engineer - Develops automated systems to streamline manufacturing operations and improve precision.

- Production Manager - Oversees manufacturing activities, coordinates resources, and ensures timely product delivery.

- Manufacturing Engineer - Focuses on the design and improvement of manufacturing systems and equipment for optimized performance.

These in-demand job roles leverage expertise in engineering principles, technology integration, and process optimization to drive manufacturing success.

Essential Skills for Success in Manufacturing Engineering

Manufacturing engineering students have diverse career paths in industries focused on product development and process optimization. Success in these roles depends on mastering both technical and interpersonal skills essential to modern manufacturing environments.

- Technical Proficiency - Expertise in CAD software, process simulation, and quality control ensures effective design and production management.

- Problem-Solving Skills - The ability to analyze complex manufacturing issues and implement innovative solutions drives continuous improvement.

- Communication Skills - Clear collaboration with multidisciplinary teams supports efficient project execution and stakeholder alignment.

Top Industries Hiring Manufacturing Engineers

Manufacturing engineering students have diverse job opportunities across multiple sectors. Top industries actively hiring manufacturing engineers include automotive, aerospace, electronics, and consumer goods manufacturing.

These industries require expertise in process optimization, quality control, and automation to improve production efficiency. Companies like General Motors, Boeing, Intel, and Procter & Gamble offer roles for manufacturing engineers focused on innovation and cost reduction. Your skills in design for manufacturability and lean manufacturing principles are highly valued in these sectors.

Advanced Technologies Shaping Manufacturing Careers

Manufacturing engineering students can pursue careers in robotics integration, automation system design, and smart factory management. Advanced technologies like AI-driven predictive maintenance and additive manufacturing are transforming job roles and skill requirements. Your expertise in these innovations positions you for impactful roles in Industry 4.0 and sustainable production systems.

Career Growth and Advancement Opportunities

Manufacturing engineering students can pursue careers as process engineers, quality control engineers, and production supervisors, each offering diverse industry experiences. Career growth often involves advancing to roles such as manufacturing manager, operations manager, or supply chain analyst, with increasing responsibility and leadership scope. Opportunities for professional development include certifications in Lean Six Sigma, automation technologies, and project management, enhancing advancement potential in dynamic manufacturing environments.

Tips for Landing Your First Manufacturing Engineering Job

| Tip | Description |

|---|---|

| Build a Strong Resume | Highlight relevant coursework, internships, and manufacturing projects. Use quantifiable results such as efficiency improvements or process optimizations. |

| Gain Practical Experience | Pursue internships, co-op programs, or part-time roles in manufacturing environments to develop hands-on skills in process design, quality control, and automation. |

| Develop Technical Skills | Master software tools like CAD, CAM, and manufacturing simulation software. Understand lean manufacturing and Six Sigma methodologies. |

| Network within the Industry | Attend engineering career fairs, join professional organizations such as ASME or SME, and connect with alumni working in manufacturing engineering roles. |

| Prepare for Interviews | Practice explaining manufacturing processes, problem-solving scenarios, and your role in team projects. Be ready to discuss industry trends like Industry 4.0 and smart manufacturing. |

| Customize Your Job Applications | Tailor each application to the specific manufacturing company and job description. Emphasize skills that match the job requirements, such as supply chain knowledge or automation expertise. |

| Be Open to Entry-Level Positions | Consider roles such as process engineer, quality engineer, or production supervisor to build a foundation and advance in manufacturing engineering careers. |

| Stay Informed about Industry Developments | Follow manufacturing innovations, advancements in robotics, and new standards for sustainability and efficiency in production processes. |

jobsintra.com

jobsintra.com