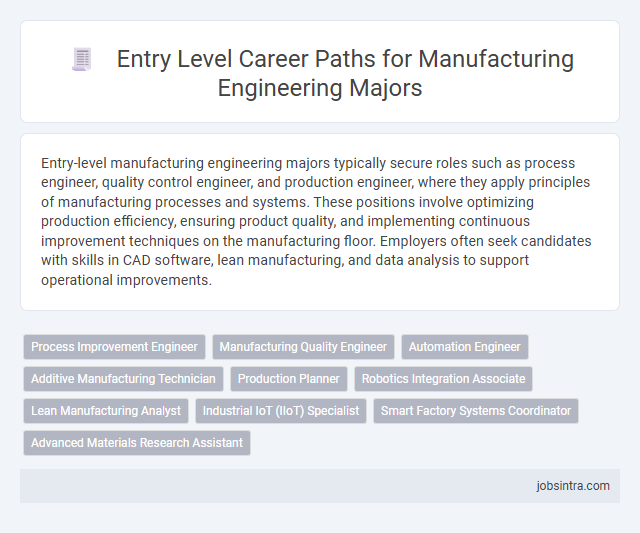

Entry-level manufacturing engineering majors typically secure roles such as process engineer, quality control engineer, and production engineer, where they apply principles of manufacturing processes and systems. These positions involve optimizing production efficiency, ensuring product quality, and implementing continuous improvement techniques on the manufacturing floor. Employers often seek candidates with skills in CAD software, lean manufacturing, and data analysis to support operational improvements.

Process Improvement Engineer

Process Improvement Engineers play a crucial role in manufacturing by identifying inefficiencies and implementing strategies to enhance production quality and reduce costs. Your analytical skills will help optimize workflows, streamline operations, and increase overall equipment effectiveness. Entry-level positions typically involve data collection, root cause analysis, and collaborating with cross-functional teams to drive continuous improvement initiatives.

Manufacturing Quality Engineer

Manufacturing Quality Engineers play a critical role in ensuring products meet industry standards and customer specifications by developing and implementing quality control processes. They analyze production data, identify defects, and collaborate with cross-functional teams to enhance manufacturing efficiency and reduce costs. Entry-level positions demand strong problem-solving skills, attention to detail, and familiarity with quality management systems such as Six Sigma or ISO standards.

Automation Engineer

An entry-level Automation Engineer in manufacturing engineering focuses on designing, programming, and maintaining automated production systems to improve efficiency and reduce costs. You will work with robotics, control systems, and software integration to optimize manufacturing processes. Strong analytical and technical skills are essential for troubleshooting and implementing automation solutions.

Additive Manufacturing Technician

Entry-level manufacturing engineering majors can pursue a career as an Additive Manufacturing Technician, specializing in 3D printing processes and technologies. This role involves operating and maintaining additive manufacturing equipment, preparing designs for production, and ensuring quality control throughout the fabrication process. Expertise in materials science, CAD software, and prototype testing supports innovation and efficiency in product development.

Production Planner

Production Planners in manufacturing engineering coordinate the scheduling of production activities to ensure efficient use of resources and timely product delivery. They analyze demand forecasts, inventory levels, and production capacity to develop detailed work schedules and optimize workflow. Strong problem-solving skills and proficiency in planning software are essential for entry-level roles in this field.

Robotics Integration Associate

Robotics Integration Associates play a critical role in manufacturing by programming, testing, and maintaining robotic systems to enhance production efficiency. You will collaborate with engineers and technicians to implement automation solutions that optimize assembly lines and reduce downtime. Entry-level positions in this role provide hands-on experience with cutting-edge robotics technology and contribute to continuous manufacturing innovation.

Lean Manufacturing Analyst

Lean Manufacturing Analysts in entry-level positions focus on identifying inefficiencies and implementing process improvements within production lines to enhance overall operational performance. They utilize tools such as value stream mapping and root cause analysis to reduce waste, optimize workflows, and increase productivity. These roles often involve collaborating with cross-functional teams to support continuous improvement initiatives and ensure adherence to lean manufacturing principles.

Industrial IoT (IIoT) Specialist

Industrial IoT (IIoT) Specialists in manufacturing engineering work to optimize production processes by integrating smart sensors, data analytics, and automation technologies. Your role involves developing and maintaining connected systems that enhance real-time monitoring, predictive maintenance, and overall operational efficiency. Entry-level positions focus on supporting IIoT implementations, troubleshooting devices, and analyzing data to improve manufacturing workflows.

Smart Factory Systems Coordinator

Smart Factory Systems Coordinator roles for manufacturing engineering majors involve optimizing automated production processes using advanced technologies such as IoT, robotics, and data analytics. You will focus on integrating smart systems to enhance efficiency, reduce downtime, and improve product quality in modern manufacturing environments. These entry-level positions require strong problem-solving skills and a solid understanding of Industry 4.0 principles.

Good to know: jobs for manufacturing engineering majors entry level

Overview of Manufacturing Engineering Careers

Manufacturing engineering majors have diverse entry-level job opportunities in the production and process optimization sectors. Roles often include process engineer, quality engineer, and manufacturing technician positions.

You will work to improve manufacturing systems, reduce costs, and enhance product quality. These careers demand strong problem-solving skills and knowledge of automation, materials, and lean manufacturing principles.

Key Skills Required for Entry-Level Roles

What key skills do entry-level manufacturing engineering majors need to succeed in their roles? Strong problem-solving abilities and proficiency in CAD software are essential for designing and improving manufacturing processes. You should also have a solid understanding of quality control, lean manufacturing principles, and basic programming for automation systems.

Top Entry-Level Job Titles for Manufacturing Engineering Graduates

Manufacturing engineering graduates enter a diverse job market with opportunities in designing, optimizing, and managing production processes. Entry-level roles focus on applying engineering principles to improve efficiency and product quality in manufacturing settings.

- Manufacturing Engineer - Responsible for developing and implementing efficient manufacturing processes and systems.

- Process Engineer - Focuses on analyzing and optimizing production workflows to enhance output and reduce costs.

- Quality Engineer - Ensures products meet quality standards through inspection, testing, and process adjustments.

You can launch your career by targeting these top positions that combine technical skills with problem-solving in manufacturing environments.

Common Industries Hiring Manufacturing Engineers

Entry-level manufacturing engineering jobs often involve roles such as process engineer, quality engineer, or production engineer. Common industries hiring manufacturing engineers include automotive, aerospace, electronics, and consumer goods. These sectors demand skills in process optimization, quality control, and automation integration to improve production efficiency.

Typical Career Progression and Advancement

Entry-level manufacturing engineering majors often start as Process Engineers or Quality Engineers, focusing on optimizing production and ensuring product standards. Typical career progression includes advancing to roles like Manufacturing Supervisor, Production Manager, or Continuous Improvement Manager, where leadership and project management skills become critical. With experience, professionals can move into senior positions such as Operations Manager or Plant Manager, overseeing entire manufacturing processes and strategic initiatives.

Certifications and Training to Boost Employability

Manufacturing engineering majors have numerous entry-level job opportunities such as process engineer, quality control analyst, and production planner. Certifications and specialized training significantly enhance job prospects in these roles.

Obtaining certifications like Six Sigma Green Belt, Lean Manufacturing, and CAD proficiency can make your resume stand out to employers. Training programs that focus on automation, robotics, and supply chain management are highly valued in manufacturing settings. These credentials demonstrate practical skills and commitment to continuous improvement, boosting employability.

Tips for Securing Your First Manufacturing Engineering Job

Entry-level manufacturing engineering jobs often include roles such as process engineer, quality engineer, and production engineer. These positions focus on optimizing manufacturing processes, ensuring product quality, and improving production efficiency.

To secure your first manufacturing engineering job, tailor your resume to highlight relevant internships, projects, and technical skills like CAD and Lean Manufacturing. Networking with professionals and joining engineering organizations can open up job opportunities in this competitive field.

jobsintra.com

jobsintra.com