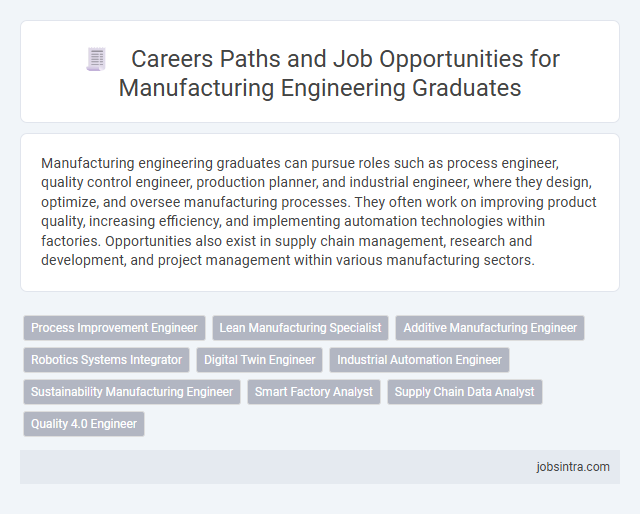

Manufacturing engineering graduates can pursue roles such as process engineer, quality control engineer, production planner, and industrial engineer, where they design, optimize, and oversee manufacturing processes. They often work on improving product quality, increasing efficiency, and implementing automation technologies within factories. Opportunities also exist in supply chain management, research and development, and project management within various manufacturing sectors.

Process Improvement Engineer

Process Improvement Engineers analyze manufacturing processes to identify inefficiencies and implement solutions that enhance productivity and quality. They use data-driven methods and lean manufacturing principles to optimize workflows, reduce costs, and minimize waste. Graduates in manufacturing engineering are well-equipped for this role, combining technical knowledge with problem-solving skills to drive continuous improvement initiatives.

Lean Manufacturing Specialist

Lean Manufacturing Specialists optimize production processes by eliminating waste and improving efficiency, making them vital in manufacturing environments. Your expertise in streamlining operations, implementing continuous improvement techniques, and applying Lean principles helps companies reduce costs and enhance product quality. Careers in this role often span industries such as automotive, electronics, and aerospace, offering opportunities to drive innovation and operational excellence.

Additive Manufacturing Engineer

Additive Manufacturing Engineers specialize in designing and optimizing 3D printing processes to create complex parts with precision and efficiency. They work closely with design teams to develop prototypes and improve product performance using advanced materials and technologies. Expertise in CAD software, materials science, and process control is essential for success in this role.

Robotics Systems Integrator

Robotics Systems Integrators design, program, and maintain automated robotic systems to improve manufacturing efficiency and productivity. They analyze production workflows and develop customized robotic solutions that streamline operations and reduce downtime. Proficiency in robotics programming, control systems, and mechanical engineering principles is essential for success in this role.

Digital Twin Engineer

Manufacturing engineering graduates can excel as Digital Twin Engineers by creating virtual replicas of physical manufacturing systems to optimize production processes. Your expertise in data analytics, simulation modeling, and IoT integration helps identify inefficiencies and predict maintenance needs. This role enhances decision-making and drives innovation within smart factories.

Industrial Automation Engineer

Industrial Automation Engineers design, develop, and implement automated systems to optimize manufacturing processes, ensuring efficiency and precision. They utilize robotics, control systems, and programming to streamline production lines and reduce operational costs. Their expertise bridges engineering principles and advanced technology to enhance industrial productivity and quality control.

Sustainability Manufacturing Engineer

Sustainability Manufacturing Engineers focus on designing and improving production processes that minimize environmental impact and promote resource efficiency. You can work on implementing renewable energy solutions, reducing waste, and optimizing material usage to support green manufacturing initiatives. These roles are crucial in driving the transition to sustainable industrial practices across various sectors.

Smart Factory Analyst

Smart Factory Analysts leverage their expertise in manufacturing engineering to optimize production processes through advanced data analytics and automation technologies. They analyze machinery performance, implement Industry 4.0 solutions, and enhance operational efficiency within smart manufacturing environments. Your skills in system integration and process improvement make you ideal for driving innovation in this high-demand role.

Supply Chain Data Analyst

Manufacturing engineering graduates can excel as Supply Chain Data Analysts by leveraging their technical skills to analyze production and logistics data, optimize inventory levels, and improve overall supply chain efficiency. They utilize statistical tools and software to identify bottlenecks, forecast demand, and enhance decision-making processes within manufacturing operations. This role requires a strong understanding of manufacturing systems combined with data analysis to drive cost reduction and streamline supply chain workflows.

Good to know: jobs for manufacturing engineering graduates

Overview of Manufacturing Engineering

Manufacturing engineering is a dynamic field that integrates principles of engineering, technology, and management to design, analyze, and improve production processes. Graduates specialize in optimizing manufacturing systems for efficiency, quality, and cost-effectiveness.

Manufacturing engineering graduates find career opportunities in industries such as automotive, aerospace, electronics, and consumer goods. Common roles include process engineer, quality control engineer, production supervisor, and product development engineer. Expertise in CAD/CAM software, lean manufacturing, and automation technologies enhances employability in these positions.

Core Skills and Competencies Required

Manufacturing engineering graduates have diverse job opportunities in industries such as automotive, aerospace, electronics, and consumer goods. Core skills and competencies are crucial for success in roles like process engineer, quality engineer, and production supervisor.

- Technical Proficiency - Expertise in manufacturing processes, CAD/CAM software, and automation technologies ensures efficient production design and implementation.

- Problem-Solving Skills - Ability to analyze process inefficiencies and develop innovative solutions enhances manufacturing productivity and quality.

- Knowledge of Quality Standards - Understanding ISO standards and Six Sigma methodologies is essential for maintaining product consistency and compliance.

Mastering these competencies helps manufacturing engineering graduates excel in optimizing production systems and advancing their career paths.

Entry-Level Job Roles for Graduates

Manufacturing engineering graduates can pursue entry-level roles such as Process Engineer, Production Engineer, and Quality Control Engineer. These positions involve optimizing manufacturing processes, ensuring product quality, and improving production efficiency. Graduates gain hands-on experience with CAD software, Lean Manufacturing principles, and automation technologies.

Advanced Career Progression Opportunities

What advanced career progression opportunities are available for manufacturing engineering graduates? Manufacturing engineering graduates can advance into roles such as Production Manager, Quality Engineer, and Process Improvement Specialist. These positions offer increased responsibilities in optimizing manufacturing systems, leading teams, and driving innovation in production technologies.

Industries Hiring Manufacturing Engineers

| Industry | Common Job Titles for Manufacturing Engineering Graduates | Key Responsibilities | Notable Employers |

|---|---|---|---|

| Automotive | Manufacturing Engineer, Process Engineer, Quality Engineer | Design manufacturing processes, optimize assembly lines, implement quality control systems | Ford, General Motors, Tesla, Toyota |

| Aerospace | Manufacturing Process Engineer, Production Engineer, Reliability Engineer | Develop production workflows, ensure compliance with aerospace standards, improve product reliability | Boeing, Lockheed Martin, Airbus, Northrop Grumman |

| Electronics & Semiconductor | Process Engineer, Equipment Engineer, Quality Assurance Engineer | Manage semiconductor fabrication processes, maintain precision equipment, oversee quality assurance | Intel, Samsung Electronics, Texas Instruments, TSMC |

| Consumer Goods & Appliances | Manufacturing Engineer, Industrial Engineer, Production Supervisor | Streamline manufacturing operations, reduce production costs, supervise manufacturing workforce | Procter & Gamble, Whirlpool, Unilever, Honeywell |

| Pharmaceutical & Biotechnology | Process Validation Engineer, Manufacturing Engineer, Quality Control Engineer | Validate manufacturing processes, ensure compliance with FDA regulations, implement quality control protocols | Pfizer, Johnson & Johnson, Merck, Novartis |

| Energy & Utilities | Manufacturing Engineer, Process Improvement Engineer, Maintenance Engineer | Optimize manufacturing for energy equipment, improve process efficiency, manage maintenance schedules | Siemens Energy, General Electric, Schlumberger, ABB |

| Heavy Machinery & Industrial Equipment | Manufacturing Engineer, Production Engineer, Quality Systems Engineer | Develop large-scale manufacturing processes, enhance quality systems, support production ramp-ups | Caterpillar, John Deere, Komatsu, Cummins |

Emerging Trends and Technologies

Manufacturing engineering graduates are increasingly finding opportunities in advanced automation, including robotics integration and smart factory development. Expertise in additive manufacturing and digital twin technologies is highly sought after to optimize production efficiency.

Emerging trends emphasize sustainable manufacturing with a focus on green materials and energy-efficient processes. Professionals skilled in Internet of Things (IoT) applications and artificial intelligence for predictive maintenance are driving innovation in the industry.

Tips for Career Growth and Success

Manufacturing engineering graduates have diverse job opportunities in process engineering, quality control, and production management. These roles involve optimizing manufacturing systems and ensuring product quality to enhance operational efficiency.

Focus on developing skills in automation, robotics, and supply chain management to stand out in the competitive job market. Continuous learning through certifications and hands-on experience can accelerate your career growth and success.

jobsintra.com

jobsintra.com