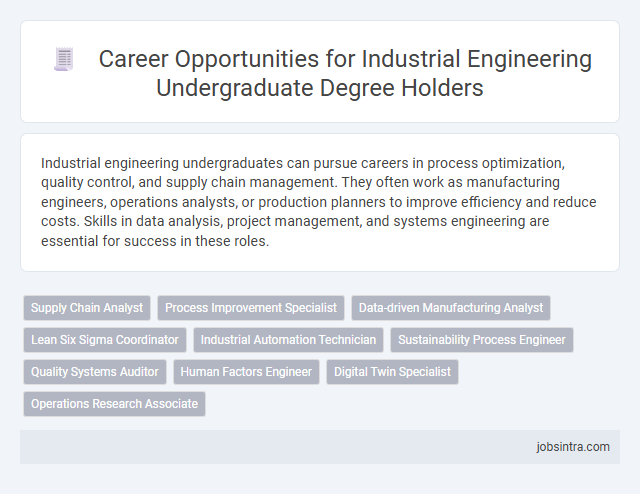

Industrial engineering undergraduates can pursue careers in process optimization, quality control, and supply chain management. They often work as manufacturing engineers, operations analysts, or production planners to improve efficiency and reduce costs. Skills in data analysis, project management, and systems engineering are essential for success in these roles.

Supply Chain Analyst

Supply Chain Analysts play a critical role in managing and optimizing the flow of goods and information within a company. They analyze data to identify inefficiencies, forecast demand, and develop strategies that reduce costs and improve delivery times. Your skills in process improvement and data analysis make you well-suited for this position, where you can drive operational excellence and support business growth.

Process Improvement Specialist

A Process Improvement Specialist identifies inefficiencies within manufacturing systems and implements strategies to enhance productivity, reduce costs, and improve quality. Your role involves analyzing workflows, utilizing lean principles, and collaborating with cross-functional teams to streamline operations. This position suits industrial engineering undergraduates seeking to optimize industrial processes and drive continuous improvement initiatives.

Data-driven Manufacturing Analyst

Industrial engineering undergraduates can excel as Data-driven Manufacturing Analysts by leveraging their skills in process optimization and statistical analysis to improve production efficiency. You will analyze manufacturing data to identify bottlenecks, reduce waste, and enhance overall operational performance. Proficiency in data visualization tools and knowledge of manufacturing systems are essential for success in this role.

Lean Six Sigma Coordinator

A Lean Six Sigma Coordinator plays a critical role in streamlining operations by implementing process improvement methodologies that reduce waste and enhance efficiency. This position requires strong analytical skills to identify inefficiencies and lead projects that drive measurable improvements across manufacturing or service environments. Your expertise in data analysis and quality management principles equips you to optimize workflows and contribute significantly to organizational success.

Industrial Automation Technician

Industrial Automation Technicians specialize in maintaining and troubleshooting automated systems to enhance manufacturing efficiency and productivity. You can work with robotics, control systems, and programmable logic controllers (PLCs) to ensure smooth operation in industrial settings. This role combines technical expertise and problem-solving skills, making it a critical position in industries focused on automation and process optimization.

Sustainability Process Engineer

Sustainability Process Engineers in industrial engineering focus on designing and optimizing manufacturing processes that minimize environmental impact while maximizing efficiency. They implement eco-friendly practices, reduce waste, and ensure compliance with sustainability regulations throughout the production lifecycle. These roles require strong analytical skills and knowledge of sustainable materials, energy management, and process improvement techniques.

Quality Systems Auditor

Quality Systems Auditors play a crucial role in industrial engineering by ensuring that manufacturing processes comply with industry standards and regulations. Your expertise in process improvement and data analysis helps identify inefficiencies and implement corrective actions to enhance product quality. This position requires strong attention to detail and a thorough understanding of quality management systems such as ISO 9001.

Human Factors Engineer

Human Factors Engineers optimize workplace systems to improve safety, efficiency, and user experience by analyzing human capabilities and limitations. They apply principles of ergonomics and psychology to design tools, equipment, and processes that enhance productivity while reducing errors and fatigue. This role is essential in industries such as manufacturing, healthcare, aerospace, and technology development.

Digital Twin Specialist

Digital Twin Specialists use advanced simulation technology to create virtual models of physical assets, enabling predictive maintenance and optimized operations. Your skills in data analysis, systems integration, and process optimization are essential for designing and managing digital twins in manufacturing, supply chain, or energy sectors. This role enhances decision-making by providing real-time insights into asset performance and operational efficiency.

Good to know: jobs for industrial engineering undergraduate

Overview of Industrial Engineering

Industrial engineering focuses on optimizing complex systems, processes, and organizations for improved efficiency and productivity. This field combines engineering, business, and management principles to solve problems related to production and operations.

- Process Engineer - Designs and improves manufacturing processes to increase efficiency and reduce waste.

- Quality Engineer - Ensures products meet quality standards through testing, inspection, and quality control methodologies.

- Operations Manager - Oversees daily operations, resource allocation, and process improvements to enhance organizational performance.

Core Skills Acquired in Industrial Engineering

Industrial engineering graduates excel in roles such as process engineering, quality control, and supply chain management. Your strong analytical and problem-solving skills make you valuable in optimizing production systems and improving operational efficiency.

Core skills acquired in industrial engineering include systems analysis, statistical quality control, and project management. Proficiency in data-driven decision-making and lean manufacturing techniques prepares you to streamline workflows and reduce waste. Mastery of tools like simulation software and ERP systems enhances your ability to design effective industrial processes.

In-Demand Career Paths for Industrial Engineering Graduates

| Job Title | Description | Key Skills | Industries |

|---|---|---|---|

| Process Engineer | Designs, implements, and optimizes manufacturing processes to enhance efficiency and reduce costs. | Lean Manufacturing, Six Sigma, Process Simulation, Data Analysis | Manufacturing, Automotive, Electronics, Pharmaceuticals |

| Supply Chain Analyst | Analyzes and improves supply chain operations to ensure timely product delivery and inventory management. | Supply Chain Management, ERP Systems, Data Analytics, Forecasting | Retail, Logistics, Consumer Goods, E-commerce |

| Quality Control Engineer | Develops quality standards and implements inspection methods to maintain product excellence. | Quality Assurance, Statistical Process Control, Root Cause Analysis, ISO Standards | Automotive, Aerospace, Food & Beverage, Healthcare |

| Industrial Engineer | Optimizes complex systems and processes by integrating people, materials, and technology. | Operations Research, Simulation Modeling, Systems Engineering, Project Management | Manufacturing, Energy, Construction, Technology |

| Operations Manager | Oversees daily production and operation functions to improve productivity and workflow efficiency. | Leadership, Process Improvement, Supply Chain Coordination, Budget Management | Manufacturing, Warehousing, Transportation, Service Industry |

| Data Analyst | Utilizes data tools to interpret operational metrics and support decision-making processes. | Data Visualization, Statistical Analysis, Python/R, SQL | Manufacturing, Finance, Consulting, Technology |

| Ergonomics Specialist | Assesses workplace design to improve employee safety, comfort, and productivity. | Ergonomic Assessment, Human Factors Engineering, Risk Analysis | Manufacturing, Healthcare, Automotive, Office Environments |

| Project Engineer | Coordinates engineering projects by managing resources, timelines, and technical requirements. | Project Management, CAD Software, Engineering Design, Communication | Construction, Manufacturing, Energy, Technology |

Emerging Industries Hiring Industrial Engineers

Industrial engineering undergraduates possess skills ideal for emerging industries such as renewable energy, advanced manufacturing, and smart technology sectors. These fields require expertise in process optimization, supply chain management, and systems analysis to drive innovation and efficiency. Your background in industrial engineering opens opportunities in startups and established companies pioneering sustainable and cutting-edge solutions.

Government and Public Sector Opportunities

Industrial engineering undergraduates possess skills in process optimization, systems analysis, and cost efficiency, making them valuable assets in government agencies focused on infrastructure, transportation, and public safety. Opportunities in the public sector include roles in policy implementation, operations management, and quality control within departments such as the Department of Transportation, Environmental Protection Agency, and public health organizations. These positions leverage industrial engineering expertise to improve service delivery, resource management, and regulatory compliance in community-focused projects.

Essential Certifications and Continued Education

Industrial engineering graduates have diverse job opportunities in manufacturing, supply chain management, quality control, and process optimization. These roles require strong analytical skills and a thorough understanding of systems engineering principles.

Essential certifications include Six Sigma Green Belt, Certified Supply Chain Professional (CSCP), and Project Management Professional (PMP). Continued education through workshops, online courses, and advanced degrees enhances career growth and technical expertise in emerging technologies.

Tips for Launching a Successful Industrial Engineering Career

Industrial engineering undergraduates have diverse job opportunities in manufacturing, supply chain, and process optimization. Securing a successful career requires strategic planning and skill development.

- Develop Technical Skills - Master software like AutoCAD, MATLAB, and simulation tools to improve problem-solving efficiency.

- Gain Practical Experience - Pursue internships or co-op programs to apply theoretical knowledge in real-world industrial settings.

- Network Professionally - Join industry associations and attend engineering conferences to connect with potential employers and mentors.

jobsintra.com

jobsintra.com