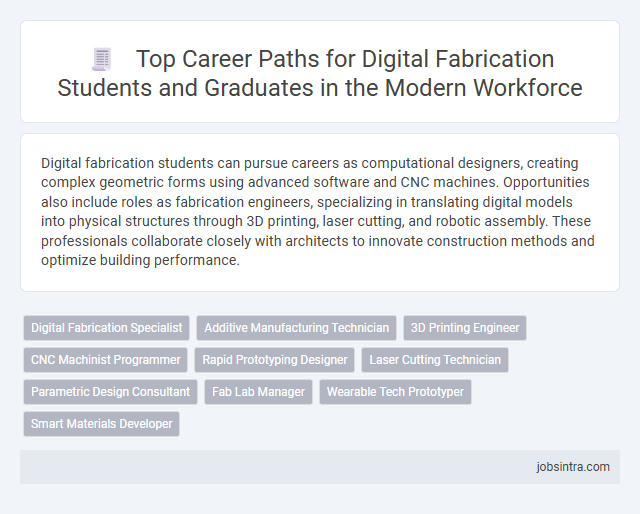

Digital fabrication students can pursue careers as computational designers, creating complex geometric forms using advanced software and CNC machines. Opportunities also include roles as fabrication engineers, specializing in translating digital models into physical structures through 3D printing, laser cutting, and robotic assembly. These professionals collaborate closely with architects to innovate construction methods and optimize building performance.

Digital Fabrication Specialist

Digital Fabrication Specialists excel in designing and producing complex components using advanced technologies such as 3D printing, CNC machining, and laser cutting. Your expertise allows you to bridge the gap between digital design and physical production, ensuring precise and efficient manufacturing processes. Careers in this field range from prototyping and product development to architectural model making and customized manufacturing solutions.

Additive Manufacturing Technician

Additive Manufacturing Technicians specialize in operating and maintaining 3D printers and other digital fabrication equipment to produce prototypes and end-use parts. Your expertise in materials, software, and machine calibration is essential for ensuring high-quality production in industries like aerospace, automotive, and healthcare. This role requires strong problem-solving skills and a deep understanding of additive manufacturing processes to optimize efficiency and product performance.

3D Printing Engineer

A 3D Printing Engineer designs, tests, and optimizes additive manufacturing processes to create prototypes and functional parts using various materials. You will work closely with product developers to improve print quality, reduce production time, and troubleshoot technical issues. Expertise in CAD software, materials science, and machine operation is essential to excel in this role.

CNC Machinist Programmer

CNC Machinist Programmers play a crucial role in digital fabrication by creating and optimizing computer-controlled machining processes. Your expertise in programming CNC machines enables the production of precise and complex components essential for industries like automotive, aerospace, and manufacturing. Mastery in CAM software and understanding machining principles are key skills that open diverse career opportunities in this field.

Rapid Prototyping Designer

Rapid Prototyping Designers create accurate and functional models to accelerate product development cycles, blending creativity with technical expertise. With skills in 3D printing, CAD software, and material science, Your ability to transform digital concepts into tangible prototypes makes you a valuable asset in industries like automotive, aerospace, and consumer electronics. This role emphasizes innovation and precision, offering opportunities to work on cutting-edge projects that shape the future of manufacturing.

Laser Cutting Technician

A Laser Cutting Technician expertly operates laser cutting machines to produce precise components from various materials, including metals, plastics, and wood. Skilled in reading technical drawings and programming CNC machines, you translate digital designs into accurate physical parts. This role is essential in industries like manufacturing, automotive, and prototyping, offering a dynamic career path for digital fabrication students.

Parametric Design Consultant

Parametric Design Consultants specialize in creating adaptable, algorithm-driven models that enhance digital fabrication processes by optimizing form and function. Your expertise in parametric software enables collaboration with architects, engineers, and manufacturers to streamline production and innovate customized solutions. This role offers opportunities to shape complex design workflows and push the boundaries of automated construction technologies.

Fab Lab Manager

A Fab Lab Manager oversees the operation and maintenance of advanced digital fabrication equipment, ensuring a safe and efficient workspace for users. You will coordinate projects, provide technical support, and manage inventory of materials and tools. Strong skills in 3D printing, laser cutting, and CNC machining are essential for success in this role.

Wearable Tech Prototyper

Wearable Tech Prototyper roles involve designing and creating innovative wearable devices that seamlessly integrate technology with everyday life. Your skills in 3D modeling, electronics, and user-centered design enable you to develop prototypes that enhance comfort, functionality, and connectivity. This job demands a blend of creativity and technical expertise to bring cutting-edge wearable solutions from concept to reality.

Good to know: jobs for digital fabrication students

Emerging Roles in Digital Fabrication

Digital fabrication students are increasingly sought after for roles involving parametric design and robotic construction. These positions require expertise in software such as Rhino, Grasshopper, and automation tools tailored for precision building processes.

Emerging roles also include specialists in additive manufacturing, focusing on 3D printing techniques for complex architectural components. Professionals adept in digital workflow management bridge the gap between design and fabrication, enhancing efficiency and innovation on construction sites.

Key Industries Embracing Digital Fabrication Talent

Digital fabrication skills open doors to various key industries such as construction, automotive, aerospace, and product design. These sectors rely heavily on advanced technologies like 3D printing, CNC machining, and laser cutting to innovate and streamline production.

You can find career opportunities in architectural firms, manufacturing companies, and research labs focused on prototyping and custom fabrication. Expertise in digital fabrication is increasingly sought after for roles involving design optimization, material science, and sustainable building methods.

Essential Skills for Digital Fabrication Careers

Digital fabrication students have a range of career opportunities in architecture, where their technical and creative skills are highly valued. Mastery of essential skills sets the foundation for success in these roles.

- CAD Modeling - Creating detailed digital designs is fundamental for producing accurate fabrication plans.

- Material Knowledge - Understanding the properties of various materials ensures optimal selection for fabrication projects.

- Software Proficiency - Expertise in software like Rhino, Grasshopper, and CNC programming drives efficient production workflows.

Your ability to combine these skills positions you for roles such as digital fabricator, CNC operator, and architectural technologist within cutting-edge design teams.

Design-Build and Construction-Tech Opportunities

Digital fabrication students in architecture find robust opportunities in Design-Build and Construction-Tech fields. Your skills in combining design with hands-on construction technology make you valuable in innovative architectural projects.

- Design-Build Coordinator - Oversees the integration of design and construction processes, ensuring seamless project execution from concept to completion.

- Construction Technologist - Implements advanced fabrication techniques and digital tools to optimize building methods and materials.

- BIM Specialist with Fabrication Focus - Develops detailed digital models that guide precise fabrication and assembly of architectural components.

Research, Innovation, and Academic Pathways

Digital fabrication students in architecture are well-suited for research roles that explore advanced construction technologies, materials innovation, and sustainability practices. Opportunities exist within academic institutions where they can contribute to developing new fabrication methods and teach emerging digital tools. Innovation-focused positions in architectural firms and tech companies allow these students to drive the integration of robotics, 3D printing, and parametric design into practical applications.

Entrepreneurship and Startups in Digital Fabrication

| Job Role | Description | Key Skills | Entrepreneurship Opportunities |

|---|---|---|---|

| Digital Fabrication Consultant | Advises architectural firms on implementing digital fabrication technologies like 3D printing, CNC milling, and laser cutting. | Technical expertise in fabrication tools, project management, client communication | Launch a consultancy startup offering tailored digital fabrication solutions for construction and design firms. |

| Product Designer for Fabrication Tools | Develops innovative hardware and software tools for digital fabrication workflows in architecture. | Product development, CAD modeling, software engineering, prototyping | Create a tech startup focused on next-gen fabrication equipment or design software targeting architects and fabricators. |

| Fabrication Facility Manager | Oversees digital fabrication labs or makerspaces, ensuring efficient operation and client support. | Operations management, technical troubleshooting, client relations | Start your own fabrication workshop or makerspace serving architects, designers, and students. |

| Entrepreneur in Sustainable Fabrication | Focuses on eco-friendly materials and processes within digital fabrication for architecture. | Material science, sustainability practices, business development | Build a green startup offering sustainable digital fabrication services or product solutions. |

| Startup Founder in Parametric Design | Creates software and tools to automate architectural design through parametric modeling linked to fabrication. | Computational design, software development, fabrication process knowledge | Develop and scale a company delivering parametric design-to-fabrication platforms for architects. |

Future Trends Shaping Digital Fabrication Professions

What future trends are shaping the career opportunities for digital fabrication students in architecture? Emerging technologies such as AI-driven design and advanced robotics are revolutionizing building processes. These innovations create demand for professionals skilled in integrating digital tools with sustainable construction methods.

How will automation impact job roles within digital fabrication in architecture? Automation will streamline repetitive tasks, allowing architects to focus on creative problem-solving and complex design challenges. This shift encourages digital fabrication students to develop expertise in programming and machine operation.

What new professions are expected to emerge for digital fabrication graduates? Roles like robotic fabrication specialist and parametric design consultant are becoming increasingly important. These jobs require a blend of technical knowledge and architectural creativity to push the boundaries of fabrication techniques.

Why is interdisciplinary collaboration vital for future digital fabrication careers? Combining skills from architecture, engineering, and computer science enhances innovation and efficiency in digital fabrication projects. Students who embrace this approach improve their employability in evolving construction environments.

How does sustainability influence the future of digital fabrication careers? The integration of eco-friendly materials and energy-efficient processes is a growing priority. Digital fabrication students trained in green construction technologies position themselves at the forefront of sustainable architectural practices.

jobsintra.com

jobsintra.com