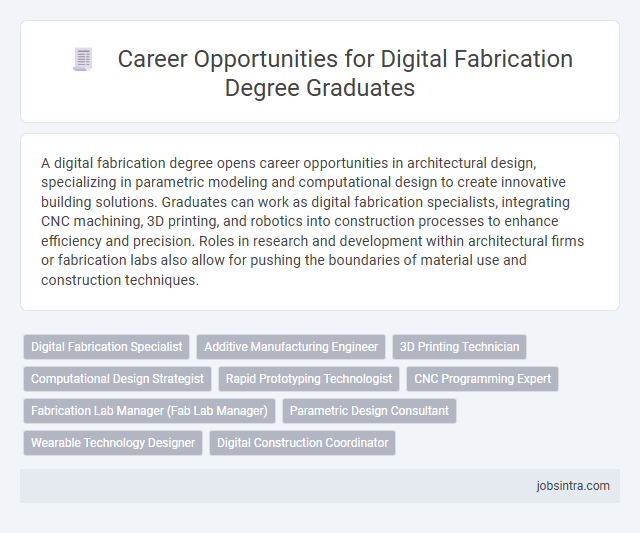

A digital fabrication degree opens career opportunities in architectural design, specializing in parametric modeling and computational design to create innovative building solutions. Graduates can work as digital fabrication specialists, integrating CNC machining, 3D printing, and robotics into construction processes to enhance efficiency and precision. Roles in research and development within architectural firms or fabrication labs also allow for pushing the boundaries of material use and construction techniques.

Digital Fabrication Specialist

A Digital Fabrication Specialist designs and operates advanced manufacturing technologies such as 3D printers, CNC machines, and laser cutters to create precise prototypes and products. Your expertise in computer-aided design software and material properties allows you to optimize production processes and innovate in fields like architecture, engineering, and product development. This role demands a blend of technical skills and creativity to turn digital models into tangible, high-quality outputs efficiently.

Additive Manufacturing Engineer

Additive Manufacturing Engineers specialize in designing, developing, and optimizing 3D printing processes to create complex prototypes and production parts with precision. They work closely with CAD designers and material scientists to enhance print quality, reduce costs, and improve manufacturing efficiency across industries like aerospace, automotive, and healthcare. Their expertise in digital fabrication technologies plays a crucial role in advancing innovative manufacturing solutions.

3D Printing Technician

3D Printing Technicians specialize in operating and maintaining 3D printers, ensuring precise fabrication of prototypes and final products. They prepare digital models, select appropriate materials, and troubleshoot printing issues to optimize output quality. Expertise in CAD software and material science enables them to support innovative manufacturing processes across various industries.

Computational Design Strategist

A Computational Design Strategist leverages expertise in digital fabrication and advanced computational tools to innovate product development and manufacturing processes. This role involves designing complex algorithms and parametric models to optimize efficiency, sustainability, and customization in fabrication projects. Professionals in this field collaborate closely with architects, engineers, and manufacturers to translate digital concepts into tangible, high-precision outcomes.

Rapid Prototyping Technologist

A Rapid Prototyping Technologist specializes in creating advanced prototypes using 3D printing, CNC machining, and other digital fabrication tools to accelerate product development cycles. You will apply expertise in computer-aided design (CAD) software and material science to produce precise, functional models for testing and refinement. This role bridges engineering and manufacturing, making it essential for innovation-driven industries seeking efficient, cost-effective solutions.

CNC Programming Expert

A CNC Programming Expert specializes in creating precise instructions for computer-controlled machines to manufacture components efficiently and accurately. Your skills in interpreting technical drawings and optimizing machine operations make you essential in industries such as aerospace, automotive, and product design. Mastery in digital fabrication software and programming languages enhances your ability to improve production quality and reduce waste.

Fabrication Lab Manager (Fab Lab Manager)

A Fabrication Lab Manager oversees the daily operations of a digital fabrication lab, ensuring that equipment such as 3D printers, laser cutters, and CNC machines run smoothly. This role involves maintaining safety protocols, training users on advanced fabrication technologies, and managing project workflows to support innovation and prototyping. Expertise in digital design software and hands-on fabrication processes is essential for optimizing lab productivity and fostering collaborative creative environments.

Parametric Design Consultant

Parametric Design Consultants leverage advanced computational tools to create adaptive, efficient architectural and product designs within digital fabrication. They specialize in developing algorithms that optimize material use, streamline production processes, and enable innovative form generation. Their expertise bridges design creativity with manufacturing technology, making them essential in industries like architecture, automotive, and aerospace.

Wearable Technology Designer

A Wearable Technology Designer creates innovative devices that seamlessly integrate electronics with clothing and accessories, enhancing functionality and user experience. This role requires expertise in digital fabrication techniques such as 3D printing, laser cutting, and smart textiles to develop customizable, ergonomic wearable solutions. Professionals in this field collaborate with engineers, fashion designers, and software developers to produce cutting-edge products for health, fitness, and lifestyle applications.

Good to know: jobs for digital fabrication degree

Overview of Digital Fabrication in Architecture

Digital fabrication in architecture integrates advanced technologies such as 3D printing, CNC milling, and laser cutting to create precise building components. Careers for graduates with a digital fabrication degree include roles like digital design technician, fabrication specialist, and BIM (Building Information Modeling) coordinator. These positions focus on optimizing construction processes, enhancing design accuracy, and enabling innovative architectural solutions.

Emerging Roles for Digital Fabrication Graduates

Digital fabrication graduates are in demand for roles such as computational designer, parametric modeler, and robotics programmer within architectural firms. These positions focus on integrating advanced manufacturing techniques with design processes to create complex, customized structures.

Emerging roles also include specialists in material innovation and digital construction management, who optimize fabrication workflows and sustainability. Your expertise in digital tools and fabrication technologies positions you uniquely for these cutting-edge career paths in the architecture industry.

Key Industries Hiring Digital Fabrication Experts

Graduates with a degree in digital fabrication possess specialized skills in computer-aided design, 3D modeling, and automated manufacturing processes. These abilities are highly valued in industries emphasizing precision and innovation.

The architecture sector actively seeks digital fabrication experts to enhance the development of complex building components through advanced CNC machining and robotic assembly. Other key industries hiring these professionals include aerospace, automotive, and product design, where digital fabrication streamlines prototyping and production.

Essential Skills and Qualifications

What career opportunities are available for graduates with a digital fabrication degree in architecture? Digital fabrication specialists can work as BIM (Building Information Modeling) coordinators, parametric designers, or digital project managers. Their expertise in CAD software, 3D modeling, and CNC machining is essential for these roles.

Which essential skills should candidates develop for jobs in digital fabrication within architecture? Proficiency in software such as Rhino, Grasshopper, and AutoCAD is crucial. Strong knowledge of materials, structural principles, and robotic fabrication methods enhances job performance.

What qualifications do employers prioritize for digital fabrication architects? A bachelor's or master's degree in architecture or digital fabrication is often required. Practical experience through internships or project portfolios demonstrating innovative use of digital tools improves employability.

How important is collaboration in digital fabrication roles in architecture? Effective communication with architects, engineers, and fabricators is vital to ensure seamless project execution. Skills in team coordination and interdisciplinary problem solving increase project success rates.

Which additional technical capabilities benefit digital fabrication professionals in architecture? Knowledge of additive manufacturing, laser cutting, and scripting languages like Python for automation contributes to higher versatility. Understanding sustainability practices related to material efficiency also adds value.

Career Growth and Advancement Paths

Graduates with a degree in digital fabrication within architecture find numerous career opportunities that blend technology with design innovation. These roles offer substantial pathways for professional growth and advancement in the evolving construction and design industries.

- Design Technologist - Develops advanced digital models and prototypes, enhancing architectural design precision and creativity.

- Digital Fabrication Specialist - Operates and programs cutting-edge machinery like CNC routers and 3D printers to produce architectural components.

- Project Manager in Digital Construction - Oversees the integration of digital fabrication processes in building projects, ensuring efficiency and quality standards.

Career progression typically leads to senior technical roles, leadership positions, or specialized consulting within digital architecture and construction technology fields.

Impact of Technology on Architectural Careers

| Job Title | Role Description | Impact of Technology | Skills Required |

|---|---|---|---|

| Digital Fabrication Specialist | Coordinates the creation of architectural components using CNC machines, 3D printers, and robotic arms. | Advances in CAD/CAM software and automated fabrication increase precision and reduce construction errors. | Proficiency in parametric design tools like Rhino and Grasshopper, knowledge of digital manufacturing processes. |

| BIM Manager | Manages Building Information Modeling to integrate design and construction workflows. | Cloud-based collaboration tools enhance interdisciplinary communication and real-time model updates. | Expertise in BIM software such as Revit, strong coordination and data management skills. |

| Computational Designer | Develops algorithm-driven designs to optimize structural performance and aesthetic complexity. | Emerging technologies like generative design and AI enable innovative architectural solutions. | Advanced programming skills, familiarity with scripting languages, and knowledge of digital design tools. |

| Robotics Integration Engineer | Implements robotic systems to automate unique architectural fabrication tasks on-site and in factories. | Cutting-edge robotics improve efficiency, reduce labor costs, and facilitate complex geometries. | Mechanical engineering fundamentals, robotics programming, and system integration capabilities. |

| Parametric Modeler | Creates adaptable architectural models that respond dynamically to environmental and structural data. | Parametric tools enable optimization of design parameters for sustainability and constructability. | Mastery of parametric software, strong analytical and design thinking skills. |

| Sustainable Fabrication Consultant | Advises on sustainable materials and fabrication methods integrating digital technologies. | Technological innovation helps reduce waste, lower carbon footprint, and promote green building practices. | Knowledge of sustainable design principles, material science, and digital fabrication techniques. |

| Architectural Technologist with Digital Focus | Bridges architectural design and digital fabrication workflows for efficient project delivery. | Use of digital tools accelerates prototyping, improves accuracy, and allows experimentation with complex forms. | Technical drawing proficiency, CAD software expertise, understanding of digital fabrication processes. |

Tips for Succeeding in Digital Fabrication Jobs

Digital fabrication specialists in architecture work with cutting-edge technologies like 3D printing, CNC milling, and laser cutting. These roles focus on turning complex designs into physical models and components with high precision.

To succeed in digital fabrication jobs, develop strong skills in CAD software and programming languages relevant to automated machinery. Emphasize continuous learning to keep up with rapidly evolving fabrication technologies. Building a portfolio showcasing innovative projects enhances employment prospects in architectural firms and fabrication labs.

jobsintra.com

jobsintra.com